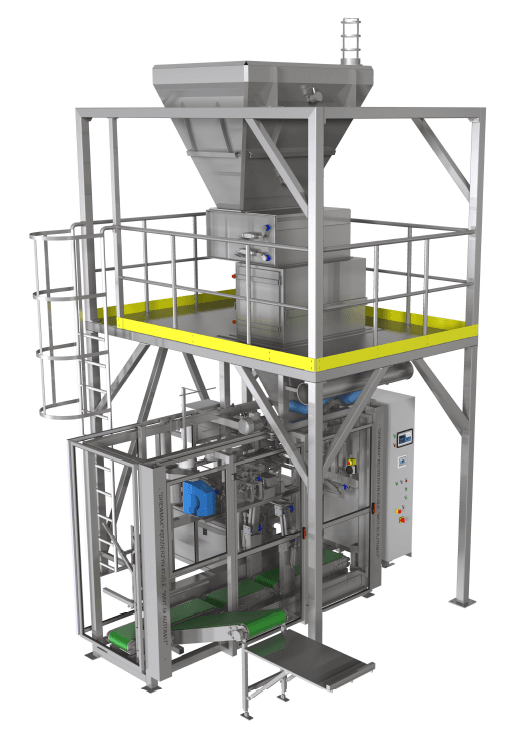

Automatic weighing and packing line type aWN/T

The combination of modern technologies and components of the best brands allowed to create an automatic weighing and packaging line of the aWN / T type. The aWN / T line is an automatic weighing and packing device for loose / granulated products with the use of open type bags.

The presented line is equipped with two weighing baskets, which are alternately filled by belt feeders with variable rotational speeds. Thanks to this combination of components, we have obtained high precision of weighing, as well as high efficiency of up to 450 portions per hour.

Basic components of the device:

- Line supporting structure with a service platform

- Automatic bag feeding device • Electronic batching scale, net type – 1 pc

- Belt dispenser – 1 pc

- Mouthpiece closed

- System for forming the upper part of the bag

- Trolley for transporting bags

- Conveyor for transporting bags

- Height adjustment system of the transport conveyor

- Top bag guiding system

- Thread continuity sensors

- Double thread sewing machine

- Side conveyor for collecting bags with a bag overturning system

- Clear control system based on Siemens PLC controller with a touch panel

- Used SEW or LENZE drives / servo drives

Optional accessories:

- Top bag wrapping system

- Crepe tape application system

- In-bag product suction system

- Filled bag vibration system

- Feeder cleaning system

- Impulse or thermal heat sealer

- Overweight buffer tank Basic

Technical parameters:

- Maximum batch weight: 50 kg,

- Minimum batch weight: 10 kg,

- Line capacity: up to 800 portions / hour. (depending on product properties and serving size)

- Bag type: open, multi-layer paper bags (up to 4 layers), recommended with an envelope bottom without side folds, PE foil bags, PP coated polypropylene bags,

- Bag width: 450 – 650mm,

- Bag length: 600 – 1100mm

- Electric supply: 3 x 400V 50Hz,

- Power demand: max. 6kW,

- Compressed air supply: 5 – 10bar,

- Compressed air consumption 400Nl / min