Close

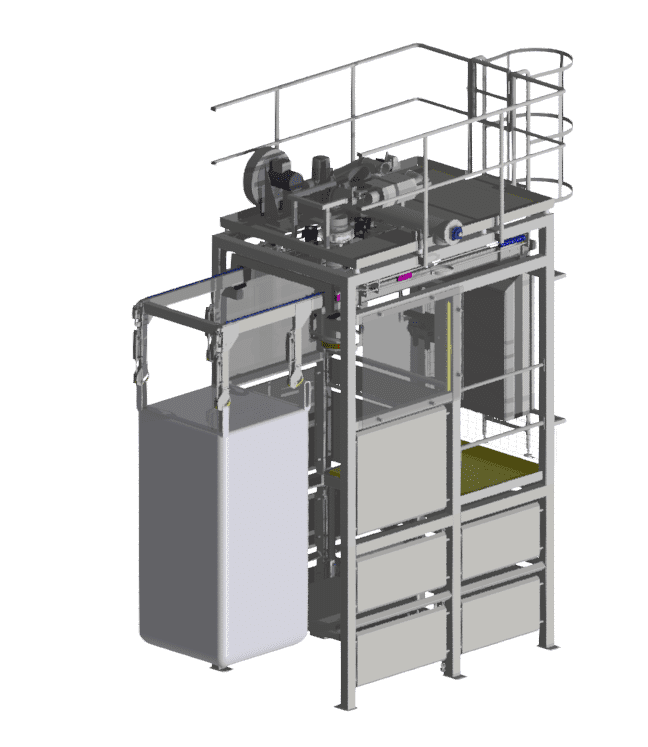

The concept of the device is based on a retractable track system on which a Big-Bag sack is suspended. The primary advantage of the device is that there is no longer a need to use pallets in the clean packing area, which is especially required in facilities involved in food production.

The device is designed so that its installation is precisely at the junction point between the packing area and the warehouse. Thanks to this positioning, the filling of the Big Bag sack, its sealing, and labeling can take place in the clean packing area. After the operator approves that the entire packaging process has been completed, an automatic gate between the packing area and the warehouse will open, and the filled sack suspended on the Big Bag frame will exit the packing zone to the warehouse area. Then, a warehouse worker will lift the pallet with the forklift along with the Big Bag sack, and the device will automatically detach it from the mounting brackets. Once the process is completed, the gate between the packing area and the warehouse will be automatically closed. This solution eliminates the need for wooden pallets in the packing area, i.e., in the clean zone, and eliminates the need to introduce transport carts into these areas.

The entire construction of the device is made of stainless steel 304, and all areas prone to contamination buildup have been eliminated by using special spacers on the platforms. The actuators have been selected from a product group intended for the food industry.

Key features/functionality for the product:

Przedsiębiorstwo Wielobranżowe DREWMAX Tadeusz Sąsiadek i Wspólnicy Spółka Jawna realizuje projekt dofinansowany z Funduszy Europejskich pn.: Wdrożenie wyników własnych prac badawczo-rozwojowych dotyczących produkcji urządzeń ważąco-pakujących. Celem projektu jest wzmocnienie innowacyjności i konkurencyjności firmy na rynku poprzez wdrożenie wyników własnych prac badawczo-rozwojowych dotyczących produkcji nowych urządzeń ważąco-pakujących. Wdrożenie wyników prac badawczo-rozwojowych w firmie pozwoli zaoferować produkty o parametrach niespotykanych do tej pory co najmniej na rynku polskim. |